Chemical Mechanism Found Behind Bloating in Rosa roxburghii Juice

Due to unexplained bloating during storage, concentrated Rosa roxburghii Tratt juice (CRRTJ) has been forced to adopt pressure-resistant packaging and high-standard cold-chain storage, substantially increasing production costs. Meanwhile, pouch rupture poses safety risks across production, transportation, and warehousing. For years, this bloating phenomenon has become a major bottleneck restricting the development of the RRT processing industry.

Recently, researchers from the Institute of Biophysics and the Institute of Geochemistry of the Chinese Academy of Sciences, in collaboration with enterprises in Guizhou Province, introduced widely targeted metabolomics into the investigation of CRRTJ bloating.

By applying a "panoramic chemical CT scan" to the juice system, the researchers successfully resolved this longstanding industrial challenge. The findings were published on January 9, 2026, in Food Chemistry.

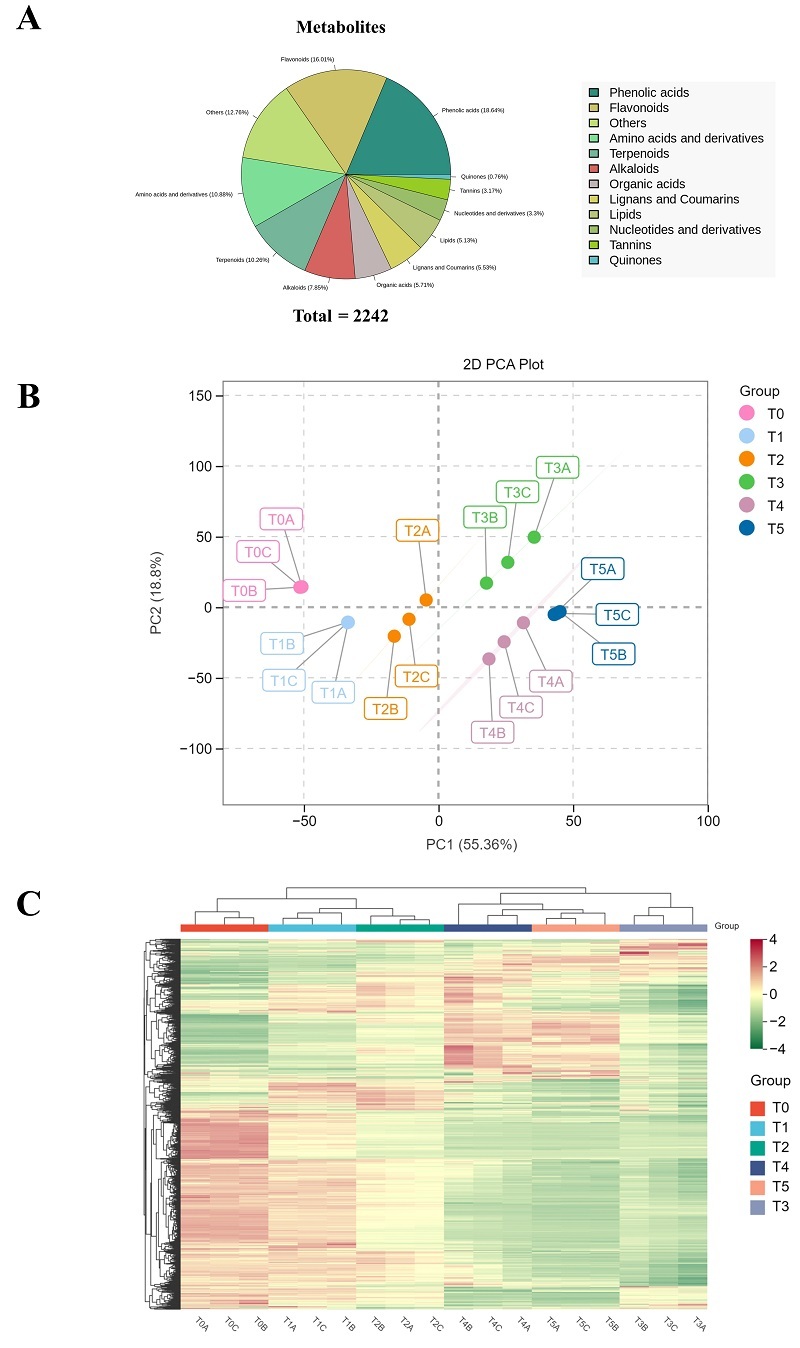

To simulate the bloating process, the researchers incubated CRRTJ at 50°C and analyzed samples taken at multiple time points using UPLC-QTRAP-MS/MS. A total of 2,242 metabolites were identified, spanning twelve chemical classes including alkaloids, flavonoids, amino acids and their derivatives.

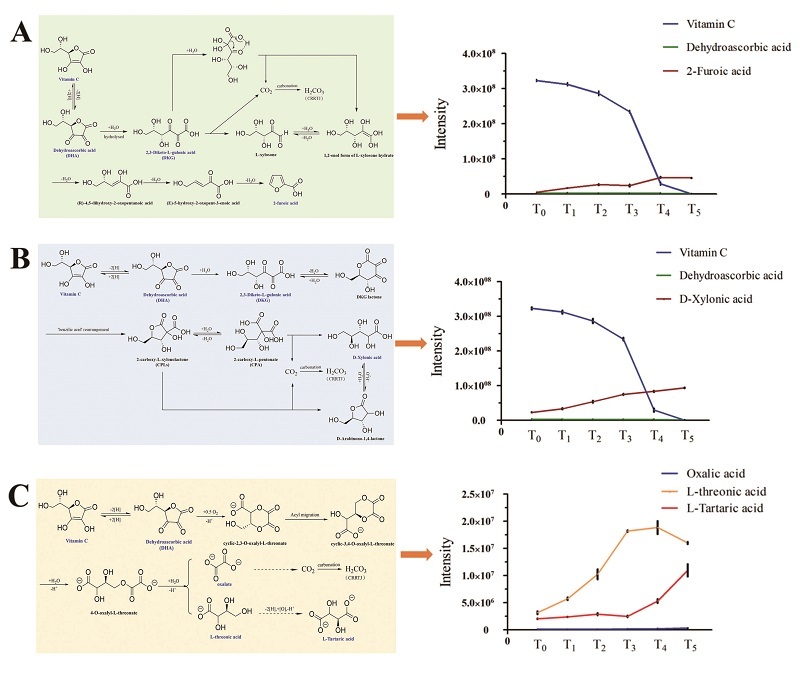

Multivariate statistical analyses revealed that during the CRRTJ bloating process, the levels of vitamin C (Vc) and its chiral isomer dehydro-D-ascorbic acid (D-Vc) steadily declined until complete depletion, while CO2 concentrations in the headspace gas increased stepwise in parallel. This strong correlation indicated that massive degradation of Vc and its chiral isomers is a likely driver of bloating.

Mechanistic investigations showed that in the uniquely acidic microenvironment of CRRTJ, Vc molecules undergo transformation through three parallel pathways: a classical oxidative pathway, a lactone-rearrangement pathway, and an oxalate-hydrolysis pathway. All three routes release CO2, and their cumulative effects are sufficient to cause significant expansion of CRRTJ packaging.

This study provides valuable reference insights for managing furanone-rich beverage systems within global supply chains, with potential to influence policy, quality frameworks and food science research worldwide.

Figure 1. Multivariate statistical analysis of CRRTJ metabolites at different bloating stages

Figure 2. Possible transformation pathways by which Vc degradation produces CO2

(Image by DONG Xianzhi's group)

Article link: https://doi.org/10.1016/j.foodchem.2026.147936

Contact: DONG Xianzhi

Institute of Biophysics, Chinese Academy of Sciences

Beijing 100101, China

E-mail: xzdong@ibp.ac.cn

(Reported by Prof. DONG Xianzhi's group)